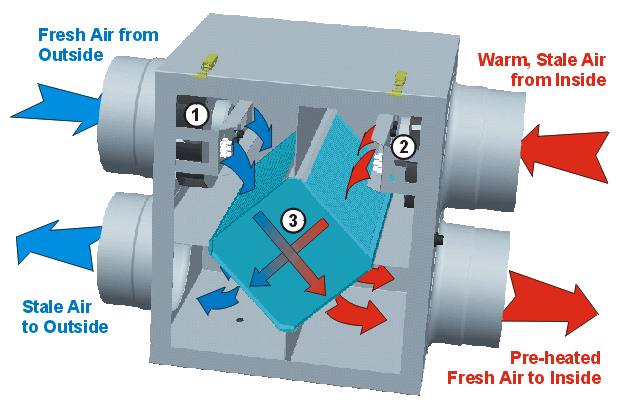

Energy Recovery Ventilator (ERV)

Heat recovery is in a plate or rotary type air-to-air heat exchange designed to provide maximum energy efficiency in ventilated systems where heated or cooled air is let out and outdoor air is let in. In applications where ventilation is required or recycling of the same air is not allowed, energy recovery wheels or plate heat exchangers are used to recover the energy from exhaust air. This reduces the initial investment in HVAC equipment and minimises operating costs. It has a big advantage of making air changes in the cold Storage by reducing the co2 levels inside the room.

Principle advantages:

- Reduce CO2 emissions

- Sensible use of fossil energy carriers

- Protects nature for future generationImproves indoor air qualityImproves employee functional efficiencyCross flow Plate Heat ExchangersThe plate heat exchanger consists of a plate stack composed of advantageously circular grooved plates, welded together. The clearances between the plates form flow ducts for flows of a heat-supplying medium and a heat-receiving medium. The plates are provided with holes which form inlet and outlet channels for the flows of the heat transfer media. At least one of the holes on the plates is located substantially in the centre of the plate.The plate heat exchanger operates on the cross flow principle. When the plate heat exchanger is provided with a partly opened mantle which connects the end plates together, and the central channel is provided with a partly opened pipe to control the flows, the plate heat exchanger is made to function both on the counter flow principle and the forward flow principle.

- Specifications of Air Ventilation Systems: –

- 1. Supply & Exhaust Blowers = Kruger -Imported

2. Frame = made of Aluminium Profiles

3. Plate Heat Exchanger = Imported from Klingenburg Germany – Cross Flow type

4. Filter = 10 Micron filters provided in the supply Air inlet and Exhaust air inlet.

5. Incoming/Outgoing = Flexible insulated duct.

6. Electrical Panel.

7. Motorised insulated Damper in Supply & Exhaust side – make Belmino.Specifications of Air Ventilation Systems: –1. Supply & Exhaust Blowers = Kruger -Imported

2. Frame = made of Aluminium Profiles

3. Plate Heat Exchanger = Imported from Klingenburg Germany – Cross Flow type

4. Filter = 10 Micron filters provided in the supply Air inlet and Exhaust air inlet.

5. Incoming/Outgoing = Flexible insulated duct.

6. Electrical Panel.

7. Motorised insulated Damper in Supply & Exhaust side – make Belmino.Applications:- Cold Storages

- Ventilation systems

- Industrial ventilation systems

- Adiabatic cooling

Add Comment